| |

Products :

Jointing Sheets

Products :

Jointing Sheets

|

|

Hindustan composites Ltd. has been in the field of manufacture of

insulating and sealing materials for over 45 years now. Compressed

asbestos fibre jointings developed and manufactured with overseas

technical backup by Hindustan composites Ltd has been more than

satisfying the needs of the industry domestically as well as

overseas.

Compressed asbestos fibre jointings are manufactured from

carefully selected chrysotile fibres, intimately blended with

suitable heat resisting binders, fillers and vulcanised into

sheets of homogenous compositions and uniform thicknesses.

To avoid the necessity of producing perfect finish on the contact

faces of a mechanical assembly, which is not only costly but quite

often impracticable, a gasket from compressed asbestos firbe

jointings enables a tight seal to be created and maintained

between separable members. The seal is effected by the yielding,

or the flow of the jointing material into the imperfections of the

joint contact faces. In this way the gasket provides an unbroken

barrier of homogenous structure through which no pathways exist

for escape of the confined media.

Highly specialized knowledge and technical skill is necessary to

manufacture adequate grades of compressed asbestos fiber jointings

to various service parameters, such as resistance to contained

fluid and pulsating loads if necessary.

The engineers and technicians involved in design, production and

maintenance are quite familiar with the wide range of compressed

asbestos fibre jointings manufactured by Hindustan composites and

hitherto marketed under the brand names of 'permanite' and

'firefly' CAF. These jointings after upgradation, wherever

necessary are now being offered under our export brand name 'FYSAX'.

Our R&D center with its highly specialized and experienced staff

continues to provide all the backup services for upgradation of

technology and products to meet the highest quality and

performance standards while keeping pace with the accelerated rate

of technological advancement and demand for excellence from the

industry.

This catalogue contains the comprehensive data in the from of

guidelines for engineers and technicians to enable them to select

the appropriate grade of jointing materials for application from

the wide range available. However the numerous parameters under

which the jointing is expected to meet manifold demands may make

the selection difficult. Our Technical cell would be most

delighted to help solve your problems promptly.

Choice Of Jointing Grade

Choice Of Jointing Grade

|

|

The choice of the grade of jointing material for any and

given condition is of paramount importance. A number of factors

need to be taken into consideration, while the choice of the

correct grade and thickness is finally made for a particular

application. |

|

|

|

Type Of Confined Media Type Of Confined Media

|

|

Resistance to attack by the confined media on

the jointing material forms the sole basis of selection. Please

refer to the Fibre jointings Recommendation chart given at the

end. Though other factors also play an important role in the

selection procedure these guidelines serve the purpose

adequately. |

|

|

|

Flange Surface Finish Flange Surface Finish

|

|

Too smooth a surface would be detrimental.

The gasket and flange surface must provide suitable friction to

reduce the chances of the gasket bursting under pressure. |

|

|

|

Concentric grooves, particularly the standard

gramophone record or spiral type are most ideal, though.

Commercial machine finish would do in most cases. However the

jointing material itself should have a high surface co-efficient

of friction, so that it may be firmly gripped between the flange

faces. This characteristic of the jointing though appears to be

insignificant for consideration, plays an important role in

reducing the possibilities of gasket burst. Hindustan Composites

pays special attention to technology of surface compounds to

meet this requirement. |

|

|

|

Gasket and Bolt Configuration Gasket and Bolt Configuration

|

|

For a given gasket stress, the possibilities

of leakages will increase as the width of the gasket decreases.

Placement of bolts to even out the stress is also an important

consideration while designing the flange. |

|

|

|

Clamping Pressure Clamping Pressure

|

|

Actual initial compression needed on a gasket

to reduce leakage to zero or to an acceptable level, also known

as minimum gasket sealing stress depends upon the following: |

|

|

-

Design of the flange and bolt configuration

-

Internal pressure of the fluid

-

Viscosity of the contained fluid and its temperature which

has an effect on the viscosity

|

|

|

|

Generally the actual clamping pressure is

increased over the minimum gasket sealing stress by multiplying

internal pressure by a factor known as the 'Gasket Factor'. As a

thumb rule, the gasket factor for liquids is 1 and that for

gases is 2.5. |

|

|

|

Choice Of Thickness Choice Of Thickness

|

|

Though there are no hard and fast rules

governing the choice of gasket thickness, the gasket should be

as thin as possible to minimize the stress relaxation. The

considerations are, dimensions and conditions of the flange. As

a guideline the following choices can be made, depending upon

the condition of the flange surface: |

|

|

| FLANGE SURFACE |

Finely ground |

Finely machine finished |

Normally machined |

Rough machined |

Well forged or die-cast |

| THICKNESS |

0.25 to 0.4 mm |

0.5 to 1.00 mm |

1.2 to 1.5 mm |

1.5 to 3.0 mm |

3.0 mm and above |

|

|

|

|

Important Characteristics Of Jointing Materials Important Characteristics Of Jointing Materials

|

|

Specifications covering the physical

properties basically help in classifying the grades of jointing

materials. For example, in recent years there has been an

increasing tendency to take tensile strength as being the total

measure of the quality and likely performance, but in reality it

is by any means, not the sole criterion to judge its possible

behavior in service. The following characteristics also play an

important role in determining how efficiently the jointing

material performs under varying operating parameters. |

|

|

-

Compressibility - A jointing material should

possess compressive characteristics so that it allows the

material to flow and conform to the flange surface with an

ability to 'bed-in' and offer necessary friction.

-

Recovery - As the jointing material should get

compressed under pressure, it should also offer resilience to

recover and maintain its sealing effect by not allowing any

'Permanent Set' due to changes in pressure of the confined

fluid and effects of its temperature, or due to flange

deflection or bolt expansion.

-

StressRelaxation - This determines the dimensional

stability of the jointing material under combined effects of

pressure and temperature. There should be a minimum tendency

of the gasket to relax its stresses under high

pressure/temperature conditions to reduce the torque loss and

maintain an effective seal.

|

|

|

|

Hindustan Composites Limited strive to

maintain these important characteristics in its jointing

material, through well formulated furnished, controlled

manufacturing process, stringent checks and balances at every

stage. |

|

|

|

Guidelines On The Use Of FYSAX AMJ Jointings Guidelines On The Use Of FYSAX AMJ Jointings

|

|

The FYSAX AMJ series of jointings are

carefully designed to perform excellently under normal fitment.

However, certain preparatory precautions would help in achieving

the best results: |

|

|

-

The flange faces must be clean and devoid of any

projections, dents, burrs, distortion, etc.

-

The OD, ID and the bolt clearances should be cut with a

sharp cutter to avoid folds and burrs.

-

Ensure that the flange surfaces are fully covered by the

gasket to avoid possible corrosion, with adequate clearance

around bolt holes to avoid folds, bulge or shear during bolt

tightening.

-

Avoid contamination of the gasket with oil, grease,

adhesives, etc.

-

Insert the gasket in between the flanges, slip one bolt

and position the gasket and place other bolts.

-

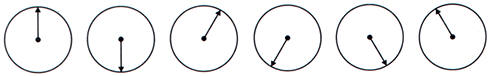

Lightly tighten in the following order and repeat the

order with full spanner pressure.

|

|

|

|

|

|

Dimensions Dimensions

|

| Range of

Nominal Thicknesses in mm |

| 0.25 |

0.4 |

0.5 |

0.75 |

1.0 |

1.2 |

1.5 |

2.0 |

3.0 |

4.0 |

5.0 |

6.0 |

|

|

|

|

Sizes Sizes

|

|

|

| Quality

Thickness |

Range (mm)

|

Sheet Size(mm) |

| |

Length

|

Width |

| All(except AMJ545 Ultra Metallic) |

1.5 & above |

1550(±50) x |

1550(±50) |

| All (except AMJ 493 ACID and

AMJ545 ultra metallic) |

All |

1850(±50) x |

1250(±50) |

| AMJ 493 ACID AND AMJ 545

Ultra-Metallic |

0.6 & above |

1850(±50) x |

1250(±50) |

| All |

All |

1500(±50) x |

1500(±50) |

|

|

|

|

Note Note

|

|

Sheet Sizes of 3200(±50)x3200(±50)

,1500(±50)x4500(±50) ,3200(±50)x 1600(±50) can also be supplied

on mutual consent. |

|

|

|